| Properties | Test Method | Performance | ||

| Hardness | ASTMD2240 | 90, 95, 98 (Shore A) | ||

| Tensile strength | ASTMD412(Die C) | ≥30MPa | ||

| Ultimate elongation | ASTMD412(Die C) | ≥300% | ||

| Tensile strength at 100% elongation | ASTMD412(Die C) | ≥7MPa | ||

| Abrasion | ASTMD5963 | <80mm³ | ||

| Low temperature resistance | -40±1℃, 22+2h, bending 90° | No break | ||

| Minimum bending radius | KTG-TPU-PN-001A0 | 5 OD | ||

| Low temperature resistance | FMVSS302 | ≤75mm/min | ||

| Resistance to bending | WI-07-07A0 | No cracking | ||

| Short-term aging (125℃/24h) | - | - | ||

| Tensile strength after aging | DIN EN 60684-2 | ≤50% | ||

| Ultimate elongation after aging | DIN EN 60684-2 | ≤50% | ||

| Long-term aging (125℃/1000h) | - | - | ||

| Tensile strength after aging | DIN EN 60684-2 | ≤50% | ||

| Ultimate elongation after aging | DIN EN 60684-2 | ≤50% | ||

| Hydrolysis resistance | Storage in water for 21 days at 80°C | - | ||

| Tensile strength after storage in water | DIN EN 60684-2 | ≤50% | ||

| Ultimate elongation after storage in water | DIN EN 60684-2 | ≤50% | ||

| Odor | VDA 270, QJ/XP 05JT.043, NES M0160, NIO-TP.GS.002, Q/CAM-546&Q/ CAM-547, VW50180, PV3900 | ≤ grade 3 | ||

| VOC | VDA278 | ≤100μg/g | ||

| Fogging | GMW3235 | ≤2mg | ||

| End-of-Life Vehicle (ELV) | GWT A A82-01, MS201-02 | Pass | ||

| Size | Inside Diameter (mm) | Wall Thickness (mm) | |

| Min. | Max. | ||

| Ø2.0 | 1.9 | 2.1 | 0.5±0.05 |

| Ø2.5 | 2.4 | 2.6 | 0.75±0.1 |

| Ø2.9 | 2.75 | 2.95 | 0.72±0.1 |

| Ø3.0 | 2.9 | 3.1 | 1±0.1 |

| Ø4.0 | 3.85 | 4.15 | 1±0.15 |

| Ø5.0 | 4.8 | 5.2 | 1.5±0.15 |

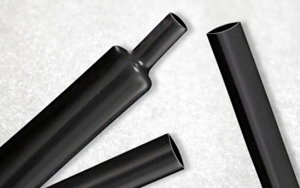

Flame-Retardant Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-FR

Flame-Retardant Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-FR

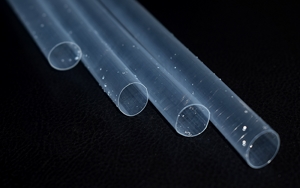

Clear Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-RX

Clear Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-RX

Halogen-Free Flame-Retardant Heat Shrink Tubing, CB-HFT

Halogen-Free Flame-Retardant Heat Shrink Tubing, CB-HFT

Low Temperature Heat Shrink Tubing, CB-HFT (LS)

Low Temperature Heat Shrink Tubing, CB-HFT (LS)

Self Closing Braided Wrap, CYG-SCE

Self Closing Braided Wrap, CYG-SCE

PET Expandable Braided Sleeving, CYG-PETN

PET Expandable Braided Sleeving, CYG-PETN

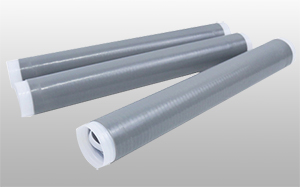

Cold Shrink Tubing

Cold Shrink Tubing

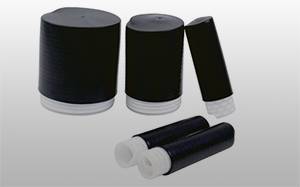

Cold Shrink End Cap

Cold Shrink End Cap

FEP Heat Shrink Tubing / Non-Shrink Tubing, CYG-FEP

FEP Heat Shrink Tubing / Non-Shrink Tubing, CYG-FEP

Fluoroelastomer Heat Shrink Tubing, CYG-FKM

Fluoroelastomer Heat Shrink Tubing, CYG-FKM