| Properties | Test Method | Performance | ||

| CYG-AMT(G) | CYG-AMT(M01) | CYG-AMT(M02) | ||

| Base material | - | PTFE | PTFE | PTFE |

| Filler | - | None | Abrasion resistant filler | High temperature abrasion resistant resin |

| Color | - | Natural | Brown | Yellow |

| Specific gravity | ASTMD792 | 2.13g/cm³ ~2.20g/cm³ | 2.0g/cm³ ~2.16g/cm³ | 2.0g/cm³ ~2.16g/cm³ |

| Melting point | ASTMD3418 | 327℃±10℃ | PTFE: 327℃±10℃ Filler: 280℃±10℃ | PTFE: 327℃±10℃ Filler degrade>450℃ |

| Continuous operating temperature | - | 200℃ | 200℃ | 200℃ |

| Tensile strength | ASTMD638 | ≥20.7MPa | ≥27.6MPa | ≥25.0MPa |

| Ultimate elongation | ASTMD638 | ≥200% | ≥150% | ≥150% |

| Wear resistance (self-developed test device) | Load: 80N R=400mm | - | ≥500000 cycles No crack, no breakdown | ≥1000000 cycles No crack, no breakdown |

| Chemical resistance | - | Excellent | Excellent | Excellent |

| Flammability | UL224 | Pass | Pass | Pass |

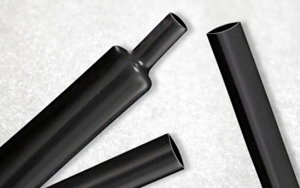

Flame-Retardant Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-FR

Flame-Retardant Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-FR

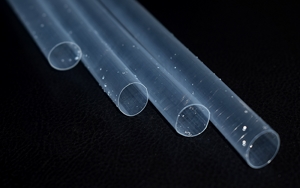

Clear Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-RX

Clear Semi-Rigid Dual Wall Heat Shrink Tubing, CYG-DWT-RX

Halogen-Free Flame-Retardant Heat Shrink Tubing, CB-HFT

Halogen-Free Flame-Retardant Heat Shrink Tubing, CB-HFT

Low Temperature Heat Shrink Tubing, CB-HFT (LS)

Low Temperature Heat Shrink Tubing, CB-HFT (LS)

Self Closing Braided Wrap, CYG-SCE

Self Closing Braided Wrap, CYG-SCE

PET Expandable Braided Sleeving, CYG-PETN

PET Expandable Braided Sleeving, CYG-PETN

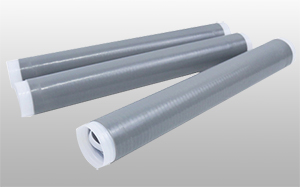

Cold Shrink Tubing

Cold Shrink Tubing

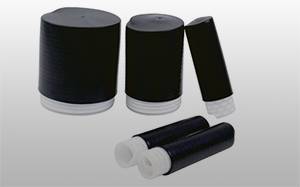

Cold Shrink End Cap

Cold Shrink End Cap

FEP Heat Shrink Tubing / Non-Shrink Tubing, CYG-FEP

FEP Heat Shrink Tubing / Non-Shrink Tubing, CYG-FEP

Fluoroelastomer Heat Shrink Tubing, CYG-FKM

Fluoroelastomer Heat Shrink Tubing, CYG-FKM